In modern industry, the demand for glass products is growing day by day. From architectural glass to home decoration glass, from automobile glass to industrial instrument glass, various glass products occupy an important position in the market. In glass product processing plants, glass cutting machines play a vital role. This article will explore the role of a glass cutter, how glass is cut in industry, and the cutting processes for materials suitable for cutting glass.

The function of glass cutting machine

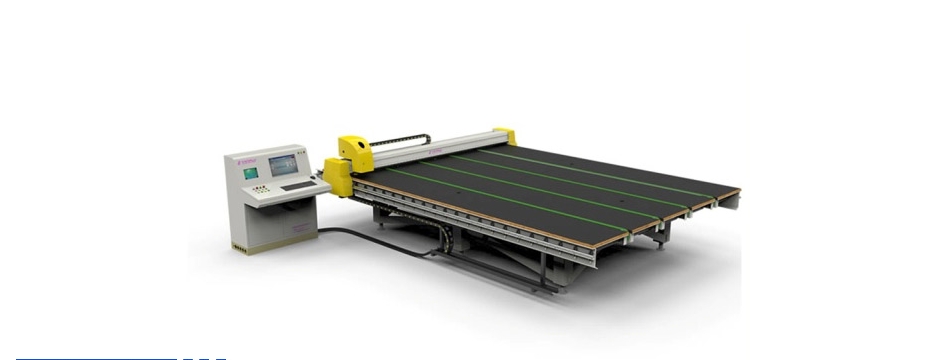

A glass cutter is a professional piece of equipment used to cut large sheets of glass into the required size and shape. Its main functions include:

Improve production efficiency: Traditional manual cutting of glass is time-consuming and laborious, but glass cutting machines can complete cutting tasks automatically and accurately, greatly improving production efficiency.

Improve product quality: The glass cutting machine uses advanced cutting technology to ensure that the cut glass plates are accurate in size and smooth in surface, improving product quality and appearance.

Reduce production costs: Automated production processes and efficient cutting methods can reduce labor costs and reduce errors and losses caused by manual operations.

Expand production capacity: Glass cutting machines can achieve continuous, high-speed cutting operations, helping to process large quantities of glass products to meet market demand.

How glass is cut in industry

In industrial production, glass cutting methods mainly include the following:

Mechanical cutting: Using professional equipment such as glass cutting machines to cut glass with blades or cutting heads, high-speed and precise cutting can be achieved, which is suitable for mass production.

Laser cutting: The use of laser beams to cut glass has the advantages of high precision, no contact, and no pollution. It is suitable for occasions where glass is processed with complex shapes and fine processing.

Waterjet cutting: Uses high-pressure water flow and abrasives to cut glass. It is suitable for glass of various hardnesses and thicknesses and can achieve an efficient and environmentally friendly cutting process.

Material cutting process suitable for cutting glass

In the processing of glass products, in addition to the glass cutting machine, it is also necessary to cooperate with the material cutting process suitable for cutting glass. Common ones include:

Drilling: Used to drill holes in glass, usually using a diamond drill bit, which can achieve precise hole diameter and hole location.

Edge grinding: Grind the edges of the cut glass to make it smooth and burr-free, improving safety and aesthetics.

Engraving: By engraving the glass surface with an engraving machine, various patterns and text can be processed for decoration and identification.

The glass cutting machine you need

If you are considering which glass cutting machine to choose, you might as well try ruifeng. As a professional glass cutting machine manufacturer, ruifeng can provide you with high-quality products and services. Welcome to contact us for detailed ordering information and services!

To sum up, the glass cutting machine plays an indispensable role in the glass product processing factory. Its role is mainly reflected in improving production efficiency, improving product quality, reducing production costs and expanding production capacity. In industrial production, mechanical cutting, laser cutting and waterjet cutting are commonly used glass cutting methods, while material cutting processes such as drilling, edge grinding and engraving can meet different processing needs.