1. Glass cutting made easy: equipment types

Diamond glass cutting machine

Known for their accuracy and durability, diamond glass cutting machines are a staple in the glass cutting industry. Its diamond-tipped blade effortlessly scores glass for clean, predictable cuts with minimal effort.

Glass scoring tools

These tools use a tungsten carbide wheel that scores the surface of the glass, creating a weak area that can easily break along the score line. They are ideal for curved or irregular cuts.

Glass pliers

Designed for small, intricate cuts, glass pliers use two opposing carbide-tipped jaws to gently bite the glass, resulting in precise and controlled cuts.

2. The cutting process revealed

Score the glass

Hold the glass firmly and position the cutter over the desired cutting line. Use a single, smooth motion and apply gentle pressure as you score the glass.

Break glass

After scoring, gently separate the two parts along the score line. Use a glass rod or pliers for added stability and precision.

Smooth edges

Use a glass grinder or fine sandpaper moistened with water to smooth out rough edges. This enhances the overall look of the cut glass.

3. Choose the right equipment for your project

The choice of glass cutting equipment depends on your specific needs and the type of glass you want to cut.

For straight cuts:

- It is recommended to use a diamond glass cutter or glass scoring tool.

For curve cutting:

- A glass scoring tool or glass pliers are ideal.

For small complex cuts:

- Glass pliers provide precision and control.

4. Glass thickness and its effects

The thickness of the glass affects the choice of cutting equipment. Thicker glass requires more force and a stronger cutter, such as a diamond glass cutter.

5. Glass cutting safety precautions

Glass cutting involves the use of sharp tools and materials. It is important to follow these safety guidelines:

- Wear protective equipment, including safety glasses and gloves.

- Secure the glass securely before cutting.

- Dispose of broken glass safely.

- Keep work area clean and free of clutter.

6. Case Study: Glass Cutting Masterpiece

Imagine using a diamond glass cutter to transform a simple sheet of glass into a complex work of art, creating stunning geometric patterns that reflect light. The precise cuts blend seamlessly into the attractive display, enhancing the ambience of the room.

7. Advantages of glass cutting equipment in various industries

Glass cutting equipment plays a vital role in the following industries:

- Architecture: Create custom-sized glass panels for doors, windows and facades.

- Art & Design: Glass molding for sculptures, mosaics and decorative pieces.

- Electronics: Precision cutting of electronic equipment and display glass.

8. Market statistics and trends

According to a recent industry report, the global glass cutting equipment market is expected to reach USD 1.2 billion by 2028, growing at a CAGR of 4.5% during the forecast period. This growth is attributed to the increasing demand for customized glass products across various industries.

9. Humorous Anecdotes: Cutting Edge

As an experienced glass cutter, I remember an interesting incident where a customer requested a custom made mirror, only to come back the next day complaining that the shape was not right. When I examined the mirror, I noticed that they had turned it upside down, giving it an unexpected "funhouse mirror" effect. The whole room was filled with laughter as we fixed the mess with corrective editing.

10. The future of glass cutting equipment

Technological advancements continue to revolutionize the glass cutting industry, with the emergence of:

- Laser Glass Cutting Machine: Provides precision and efficiency when shaping complex glass designs.

- Water jet glass cutting machine: Uses high-pressure water jets to cut glass with minimal thermal deformation.

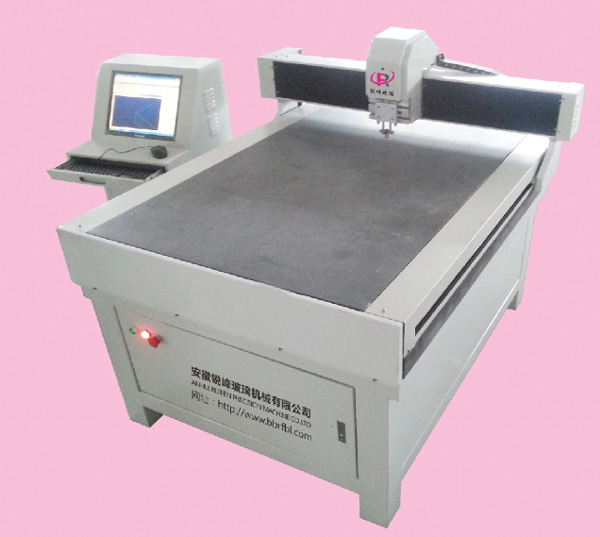

- CNC glass cutting machine: automated system that enables complex and repeatable cutting for mass production.

Conclusion

Utilizing the versatility of glass cutting equipment, you can transform ordinary glass into extraordinary creations. From crafting custom decorative pieces to realizing architectural visions, these tools inspire your imagination and unlock the endless possibilities of glass crafting. Remember to put safety first, choose the right equipment for your project, and have fun shaping glass with precision.