The pressure used by a glass cutting machine depends on a variety of factors, including the model of the cutting machine, the thickness and hardness of the glass being cut, etc. Different cutting machines may have different pressure setting ranges to accommodate different cutting needs. When using a glass cutting machine, it usually needs to be adjusted and optimized according to the specific situation.

Fully automatic glass cutting machines play an important role in the modern glass processing industry. They can efficiently complete various cutting tasks, improving production efficiency and product quality. When choosing a suitable glass cutting machine, factors such as production needs, technical parameters, and degree of automation need to be considered.

First of all, production needs are one of the key factors in choosing a glass cutting machine. Different cutting machines are suitable for different types of processing, such as straight line cutting, curve cutting, internal and external circle cutting, etc. Choosing the appropriate cutting machine model according to actual needs can improve work efficiency and processing quality.

Secondly, the scale of production is also one of the factors to consider when choosing a glass cutting machine. For enterprises with larger production scale, they need to choose cutting machines that can meet high production capacity requirements. For smaller production companies, they can choose a cutting machine suitable for their production scale and give full play to their advantages.

In terms of technical parameters, cutting accuracy is an important consideration. The cutting accuracy of the glass cutting machine directly affects the quality and accuracy requirements of the processed products. Therefore, choosing a model with high-precision cutting capabilities can improve product quality and customer satisfaction.

In addition, cutting speed is also one of the factors that needs to be balanced. High-speed cutting can improve production efficiency, but may sacrifice certain cutting accuracy. Therefore, when choosing a glass cutting machine, you need to balance cutting speed and cutting accuracy according to actual needs.

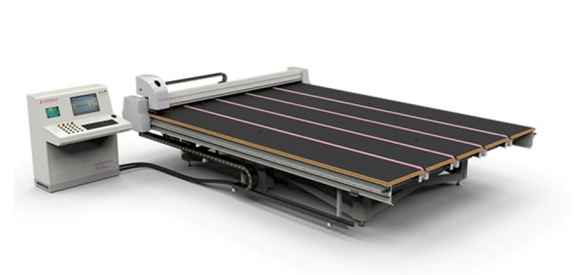

The best fully automatic glass cutting machine

If you are considering which glass cutting machine to choose, you might as well try Ruifeng. As one of the top glass cutting machine manufacturers, they can provide you with quality products and perfect services. Welcome to contact us for more information about glass cutting machines. content!

Finally, the degree of automation is also an important consideration. The fully automatic glass cutting machine can realize automatic loading, automatic cutting, automatic unloading and other functions, greatly improving production efficiency and operation convenience. Choosing a cutting machine with a high degree of automation can reduce manual operations and improve production efficiency.

To sum up, choosing a suitable fully automatic glass cutting machine requires comprehensive consideration of production needs, technical parameters, degree of automation and other factors. As an excellent glass cutting machine manufacturer, Ruifeng provides high-quality products and complete services to meet various cutting needs. If you have any needs or questions about glass cutting machines, please contact us for more information about glass cutting machines.