In this article, we will explore the benefits of utilizing fully automated glass cutting lines, highlighting the precision, efficiency and quality they bring to the glass manufacturing process.

precision and accuracy

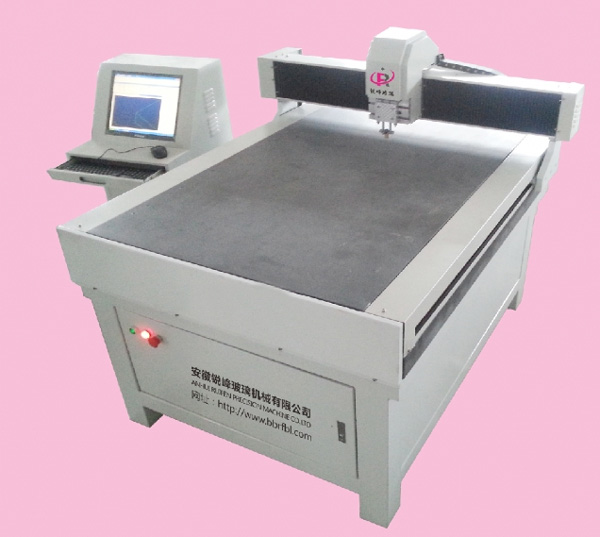

One of the main advantages of a fully automatic glass cutting line is its exceptional precision and accuracy. These cutting lines use advanced technology such as computer numerical control (CNC) systems and laser scanning to ensure precise measurements and minimize errors. The automated nature of these systems eliminates human variation, resulting in consistently accurate cuts and reduced material waste.

Improve efficiency and productivity

Fully automatic glass cutting lines significantly improve production efficiency and productivity. These systems are designed to process large volumes of glass quickly and accurately, minimizing downtime and maximizing throughput. With automated loading and unloading mechanisms, continuous cutting processes and integrated optimization software, these cutting lines streamline the manufacturing process, resulting in shorter turnaround times and increased productivity.

Reduce waste and save costs

By leveraging advanced optimization algorithms, fully automated glass cutting lines maximize material utilization and minimize waste. These systems analyze the size and shape of the glass sheets to be cut, optimizing the layout to minimize the amount of remaining scrap. The reduction of waste not only contributes to environmental sustainability but also leads to significant cost savings by minimizing raw material consumption.

Improve quality and consistency

The automated nature of fully automatic glass cutting lines ensures consistent, high-quality results. By eliminating human error and variability, these systems enable precise and uniform cuts, producing glass products with superior edge quality and dimensional accuracy. Consistent quality achieved through automation enhances the overall aesthetics and functionality of the glass, meeting the stringent requirements of various industries.

Enhance workplace safety

Automation of the glass cutting process significantly improves workplace safety. Fully automated cutting lines reduce the risks associated with glass handling and cutting by minimizing manual handling of glass sheets and reducing the need for manual cutting tools. This creates a safer working environment for employees, reducing the potential for accidents and injuries.

Excellent fully automatic glass cutting line

How to choose an excellent fully automatic glass cutting line? If you don’t know how to choose a high-quality fully automatic glass cutting line, you might as well try ruifeng. As a professional fully automatic glass cutting line manufacturer, ruifeng can provide you with high-quality products and excellent services. Welcome to contact us to get various Various glass cutting lines!

Fully automatic glass cutting lines have revolutionized the glass processing industry, offering numerous advantages that increase precision, efficiency and quality. From precision cutting to increased productivity and cost savings, these cutting lines are changing the way glass is made. By embracing automation, glass manufacturers can achieve higher levels of productivity, consistent quality and greater workplace safety, placing themselves at the forefront of industry advancements.