In the glass industry, it is very important to use a high-quality, adaptable glass cutting machine. But with so many different types and models of cutting machines available on the market, how do you choose the one that suits your needs? Here are some practical tips to help you choose the right glass cutter.

Determine your needs: First, it is crucial to identify your needs. You need to consider factors such as the cutting size range of the cutting machine, the type of material being cut (such as flat glass, mirror glass, etc.), cutting accuracy requirements, and budget constraints. Knowing your needs can help you narrow down your options and find the cutter that works best for you.

Quality and brand reputation: Choosing a well-known brand of glass cutting machine can better guarantee its quality and performance stability. Understand the reputation and user reviews of each brand, and choose those that have a good reputation and are proven.

Cutting accuracy and speed: Cutting accuracy is one of the important indicators for measuring the performance of a cutting machine. For projects that require high-precision cutting, choosing a model with higher precision is necessary. Also consider cutting speed to ensure the job can be completed within a reasonable time.

Power and Speed: Choose the appropriate power and speed based on your needs. Generally speaking, the higher the power, the thicker the cutting thickness and the faster the speed. However, too high power may result in greater energy consumption, so the choice should be based on actual needs.

Versatility and adaptability: If you need to handle multiple types of glass or perform complex cutting tasks, consider choosing a model with more features and adaptability. For example, some cutting machines are equipped with CNC systems, which can achieve more precise cutting and can also perform special operations such as special-shaped cutting.

Safety performance: The safety performance of the cutting machine is very important. Make sure the model you choose has safety protection devices, such as emergency stop buttons, protective covers, etc., to reduce the occurrence of accidental injuries.

Price and after-sales service: Finally, compare the prices and after-sales service of different brands and models of glass cutting machines. Be careful not to just look at the price and ignore the importance of after-sales service. Choose a supplier that provides high-quality after-sales service and competitive prices to ensure long-term use and maintenance of the cutting machine.

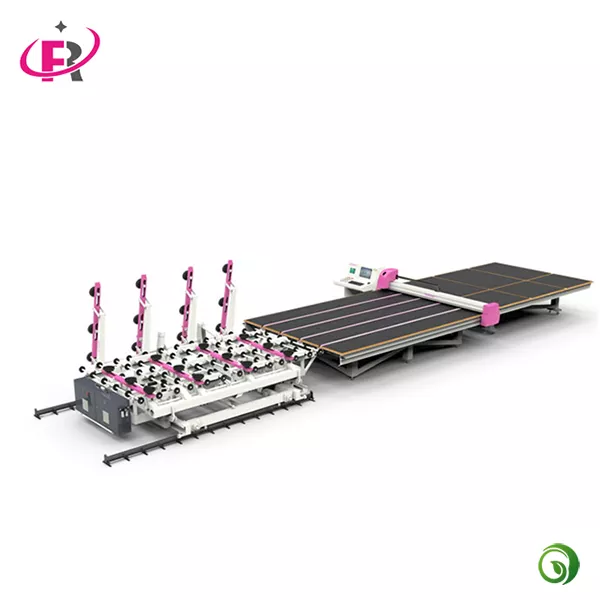

Best glass cutting machine

If you are still wondering which glass cutting machine to choose, I recommend you consider Ruifeng. As a professional manufacturer of glass cutting machines, Ruifeng has rich production technology and experience, and provides complete after-sales service. Their products have reliable quality and stable performance, and can meet the cutting needs of different sizes and materials. By choosing Ruifeng, you can enjoy high-quality cutting machines and professional after-sales support, improve work efficiency and obtain satisfactory cutting results.

All in all, choosing the right glass cutting machine is key, and you need to fully consider factors such as your needs, quality and brand reputation, cutting accuracy and speed, power and speed, functional adaptability, safety performance, as well as price and after-sales service. By choosing carefully, you'll be able to find the glass cutting machine that best suits your needs, improving work efficiency and quality.