In today's fast-paced manufacturing landscape, precision and efficiency are paramount. Nowhere is this more evident than in industries reliant on glass processing, such as construction, automotive, electronics, and furniture. The advent of полуавтоматические станки для резки стекла has transformed the way glass is handled, paving the way for enhanced productivity, consistency, and safety.

Evolution of Glass Cutting Technology:

Glass cutting has come a long way from manual methods to sophisticated automated solutions. Traditional glass cutting involved skilled artisans meticulously scoring and breaking glass sheets by hand, a process prone to inconsistencies and errors. However, with advancements in technology, полуавтоматические станки для резки стекла have emerged as game-changers, offering precision and efficiency like never before.

Key Features and Components:

Semi-automatic glass cutting machines boast an array of features designed to streamline the cutting process. These include precision cutting mechanisms equipped with diamond or carbide blades capable of making accurate cuts with minimal chipping. Automated measurement and alignment systems ensure precise dimensions, reducing material wastage and improving yield rates. User-friendly interfaces allow operators to program cutting parameters effortlessly, while safety measures such as interlocks and guards protect personnel from potential hazards.

Advantages Over Manual Methods:

The advantages of semi-automatic glass cutting machines over manual methods are profound. Firstly, they significantly increase productivity by automating repetitive tasks, enabling manufacturers to meet tight deadlines and customer demands efficiently. Moreover, these machines deliver consistent quality, ensuring uniformity across glass products and minimizing defects. By minimizing human error, semi-automatic machines reduce the risk of costly mistakes and material wastage, ultimately leading to cost savings. Importantly, they prioritize operator safety, mitigating the risks associated with manual handling of glass sheets.

Applications Across Industries:

The applications of semi-automatic glass cutting machines span various industries, each benefiting from their precision and versatility. In construction, these machines are utilized for cutting glass panels used in buildings and facades, enhancing aesthetics and energy efficiency. Automotive manufacturers rely on them for cutting windshields, windows, and mirrors, meeting stringent safety standards while optimizing vehicle performance. In the electronics sector, semi-automatic machines are indispensable for cutting display screens and touch panels with utmost precision, facilitating the production of high-quality electronic devices. Additionally, in the furniture industry, these machines are instrumental in crafting glass tabletops and shelves, adding sophistication to interior décor.

The Role in Modern Manufacturing:

Semi-automatic glass cutting machines play a pivotal role in modern manufacturing, driving efficiency, precision, and innovation across industries. By streamlining the cutting process and minimizing human intervention, these machines optimize resource utilization and enhance overall productivity. Their ability to deliver consistent quality ensures customer satisfaction and reinforces brand reputation. Furthermore, by reducing waste and promoting sustainability, they align with the growing emphasis on eco-friendly manufacturing practices. As technology continues to evolve, semi-automatic glass cutting machines are poised to remain indispensable assets in the manufacturing landscape, empowering businesses to stay competitive in a dynamic market.

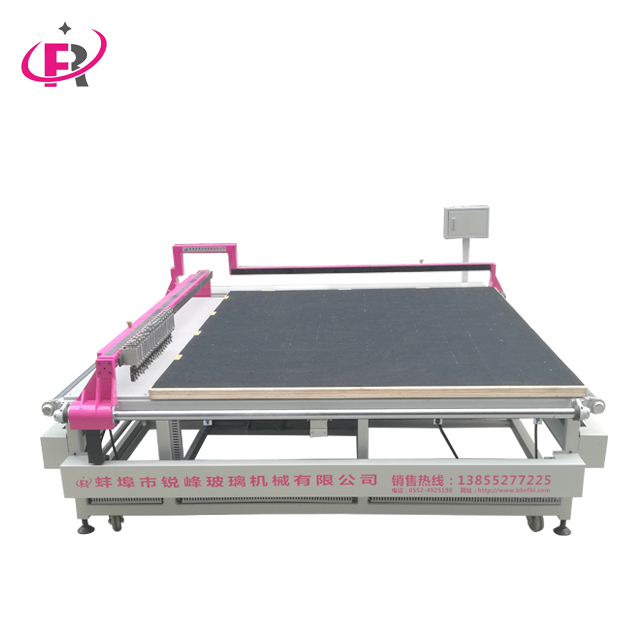

If you want to get a high-quality semi-automatic glass cutting machine, you might as well try ruifeng. As a professional semi-automatic glass cutting machine manufacturer, ruifeng can provide you with high-quality products and services. Welcome to contact us for detailed ordering information.

In conclusion, semi-automatic glass cutting machines represent a paradigm shift in glass processing, revolutionizing precision and efficiency in modern manufacturing. With their advanced features and versatile applications, these machines are driving innovation and reshaping industries, paving the way for a future characterized by enhanced productivity, quality, and sustainability.