Various glass cutting operations include architectural glass, automotive glass, craft glass, round glass, decorative glass, cabinet glass coated glass, home appliance glass, solar glass, kitchen glass, bathroom glass, lenses, handicraft glass, and splicing glass.

Characteristics:

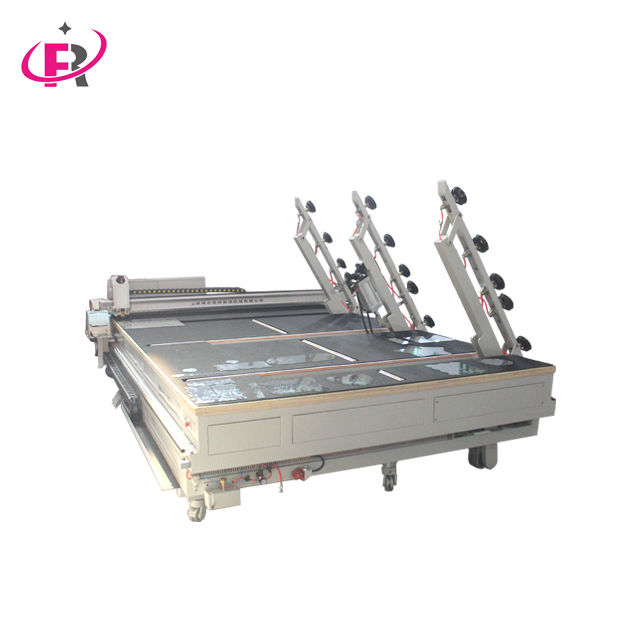

This machine has a small footprint, simple and safe operation, fast speed and high accuracy. It can be commanded to walk freely in the workshop using a remote control, with high cost-effectiveness, high safety, high cutting rate, good stability, full functionality, and more labor-saving.