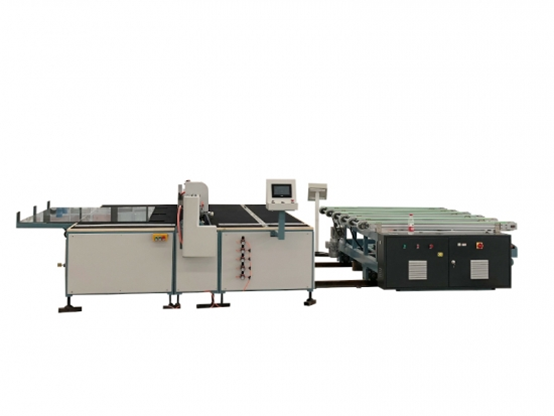

RF-2000-9 Single Side Linear Vertical Glass Grinding Machine:Suitable for construction, decoration, furniture, home appliance glass, shower rooms, glass display cabinets, coffee tables, fish tanks, frameless glass doors, it is an essential glass edging machine for glass deep processing plants.

RF-2000-9 Single Side Linear Vertical Glass Grinding Machine

Mechanical parameter:

-

★Voltage:380V-50HZ

-

★Installed power:19.5kw

-

★Conveying speed:0.5-5.5m/min

-

★Minimum size of processed glass:100 * 100mm

-

★Maximum size of processed glass:2000 * 1800mm

-

★Processing glass thickness :3-25mm

-

★Body weight :3000kg

Product detail diagram

Scope of application

Technical index

| Voltage | 380V-50HZ |

| Installed power | 19.5kw |

| Conveying speed | 0.5-5.5m/min |

| Minimum size of processed glass | 100*100mm |

| Maximum size of processed glass | 2000*1800mm |

| Processing glass thickness | 3-25mm |

| Body weight | 3000kg |

| External dimensions (length * width * height) | 6800*1000*2500mm |

Equipment characteristics:

1. Equipped with a dedicated motor for high-precision glass edge grinding machines, all bottom edge chamfers use dedicated grinding head motors, making the glass edge grinding machine grind glass like mud during the grinding process. We guarantee 100% copper core motors and guarantee a one-year warranty for grinding head motors.

2. The quality inspection specialist has controlled the inspection error of the grinding machine beam within plus or minus 0.05mm, ensuring the accuracy of the beam. Therefore, the service life of the machine is beyond doubt. In this regard, our company is leading in the same industry. Some manufacturers are not equipped with quality inspectors due to cost constraints.

3. It has a unique overload protection circuit, which automatically stops grinding when the motor is overloaded, providing safety assurance for the grinding head motor.

4. The pressure plate is made of POM material and undergoes a special grinding process. When grinding long glass, there will be no phenomena such as large or small chamfers, uneven chamfers, or broken glass.

5. Both the front and rear beams are equipped with wear-resistant inlays to protect the beams from wear and provide assurance for high-strength work.

6. Adopting stepless speed adjustment, with a large adjustable range and smooth speed change.

When adjusting different glass thicknesses, you can refer to the front beam digital table for adjustment.

8. The front chamfer motor moves synchronously with the front beam, and when the glass thickness becomes thicker or thinner, there is no need to readjust the chamfer width.

9. A unique streamlined control electrical box that keeps up with the times.

10. The grinding head water tank is made of high-quality stainless steel, and the edges of the stainless steel have undergone special processes, which will not harm people.

Our Services Advantage

We do not only offer excellent products , but also perfect aftersales-sevice For machines fer saes-sevice is very important choosing topleademanufacturer , njoying perfect after sales-service.

Collaborate with us-

Inquiry Stage

-

Visit Stage

-

Production Stage

-

Delivery Stage

-

After sales-service