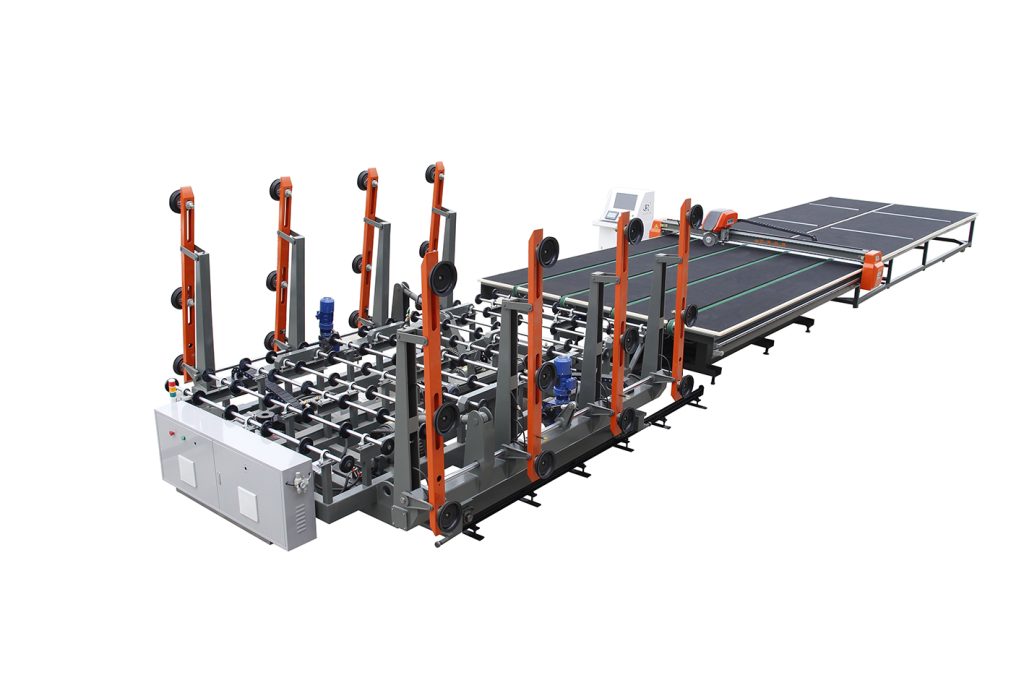

CNC glass-cutting machine is an indispensable and important equipment in modern industrial production. Its efficient and precise cutting capabilities play a key role in the field of glass processing. However, maximizing productivity requires a series of measures to optimize cutting parameters, apply automation technology, and select and maintain tools.

Optimize cutting parameters

Cutting parameters directly affect the production efficiency of CNC glass cutting machines. By adjusting parameters such as cutting speed and cutting depth, a more efficient cutting process can be achieved. For different materials and cutting needs, cutting parameters need to be accurately optimized to ensure cutting quality while improving production efficiency. It is recommended to conduct experiments and adjustments according to the actual situation, and continuously optimize parameter settings to achieve the best production efficiency.

Application of automation technology

The application of automation technology in CNC glass cutting machines can significantly improve production efficiency. By realizing functions such as automatic loading and unloading, manual operations can be reduced, production efficiency improved and production costs reduced. Advanced automation technology can not only improve production efficiency, but also improve the overall intelligence level of the production line, giving enterprises greater competitive advantages.

Tool selection and maintenance

The selection and maintenance of cutting tools are crucial to the productivity of CNC glass cutting machines. Choosing the right tool type and material can improve cutting quality and efficiency. Regularly inspecting and replacing worn knives is a critical step in maintaining good cutting results. In addition, correct tool care and maintenance can also extend the service life of the tools, reduce replacement costs, and further improve production efficiency.

In actual production, by optimizing cutting parameters, applying automation technology, and selecting and maintaining cutting tools, the production efficiency of CNC glass cutting machines can be effectively improved, and the overall operating efficiency of the production line can be improved, thereby achieving higher quality and more efficient production. Continuously exploring and applying new technologies and continuously improving production processes will be one of the keys for enterprises to improve their competitiveness.

How to maintain and maintain CNC glass cutting machine

The correct maintenance and upkeep of CNC glass cutting machines is the key to ensuring long-term stable operation of the equipment and maintaining efficient production. Here are some key maintenance and care guidelines:

Regular cleaning: Keeping your CNC glass cutting machine clean is the first step in maintenance. Regularly clean the machine surface, cutting area and slide rails to prevent dust and impurities from accumulating and affecting the cutting effect.

Lubrication and maintenance: Regularly lubricate and maintain the slide rails, transmission chains and other components of the CNC glass cutting machine to ensure smooth operation between components and reduce wear.

Tool maintenance: Regularly check the wear of the tools and replace severely worn tools in a timely manner to ensure cutting quality. At the same time, keeping your knives clean and sharp is an important maintenance step.

Electrical system inspection: Regularly check the electrical system of the CNC glass cutting machine to ensure that the electrical connection is firm and reliable to avoid equipment shutdown due to circuit failure.

Regular maintenance: Develop a regular maintenance plan based on equipment usage and manufacturer recommendations. Regular inspection, maintenance and upkeep of key components can extend the life of your equipment.

Through regular maintenance and upkeep, the stability and reliability of CNC glass cutting machines will be effectively improved, and production efficiency will be further improved. At the same time, timely detection and resolution of problems can reduce equipment failure rates, reduce maintenance costs, and ensure the continuous and efficient operation of the production line.

Excellent CNC glass cutting machine

If you want to get a high-quality CNC glass cutting machine, but don’t know how to buy it, you might as well try ruifeng. As a professional CNC glass cutting machine manufacturer, ruifeng can provide you with high-quality products and excellent services. Welcome to contact us to get Detailed ordering information and services!