When it comes to glass cutting, clean cuts are crucial. By correctly selecting and using a glass cutting machine, precise and clean cutting can be achieved. To this end, the following article will introduce the glass cutting machine as an effective tool for achieving clean cutting, and explain its working principle, preparation, cutting steps, and post-cutting treatment. As well as its advantages and usage tips.

Importance of glass cutting

Whether you're making glass windows and doors, furniture, or art, clean cuts are crucial. Precise and clean glass cuts can improve the aesthetics of the product while reducing the difficulty of subsequent processing steps.

How glass cutting machine works

A. Structure Overview

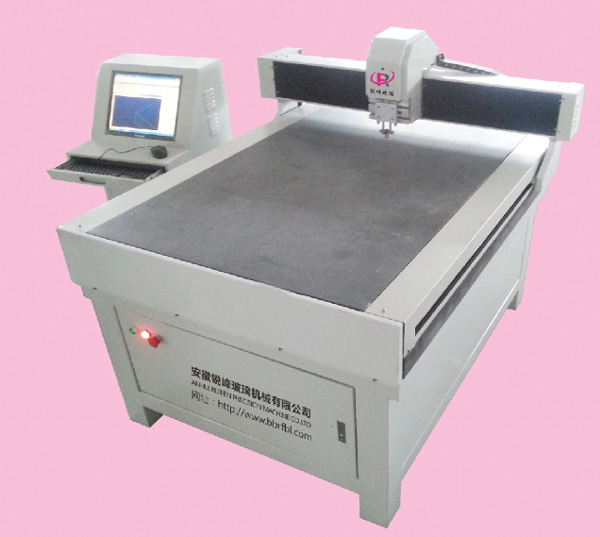

Glass cutting machines usually consist of a cutting head, a base, a control panel and a conveyor system.

B. Analysis of cutting principle

The glass cutting machine cuts the glass through the cutting knife or cutting wheel on the cutting head. The cutting knife or cutting wheel is instructed by the control panel to cut along the predetermined cutting line.

Preparation

A. Select the appropriate glass cutting machine

Choose the appropriate model according to your needs, taking into account factors such as glass thickness, cutting shape, and work efficiency.

B. Prepare workbench and safety equipment

Make sure the work surface is flat and stable, and wear safety equipment such as protective glasses and gloves to ensure safety.

Cutting process steps

A. Determine the cutting line

Mark the intended cutting line on the glass to ensure accuracy.

B. Adjust cutting machine parameters

Adjust the parameters of the cutting machine, such as knife speed, knife pressure, etc., according to the thickness of the glass and the cutting line.

C. Start cutting

Start the cutting machine and cut according to the preset program.

D. Precautions

During the cutting process, make sure the glass surface is clean and free of impurities, and ensure the normal operation and operation of the cutting machine.

Post-cut processing

A. Clean the cutting edge

Use a polishing tool or grinding wheel to process the cutting edge to ensure a smooth and flat cut.

B. Check cutting quality

Check the quality of the cuts to make sure they are clean and free of burrs.

C. Safely store glass fragments

The cut glass fragments need to be stored properly to avoid hurting people.

in conclusion

As an important tool to achieve clean cutting, glass cutting machine plays an irreplaceable role in the field of glass processing. Proper selection and use of glass cutting machines can achieve precise, clean cutting, improve work efficiency and reduce the occurrence of human errors. When handling glass cutting work, always exercise caution and safety first.

If you want to get a high-quality glass cutting machine, but don’t know how to choose, you might as well try ruifeng. As a professional glass cutting machine manufacturer, ruifeng can provide you with high-quality products and services. Welcome to contact us for detailed ordering information. and service!