A glass cutting machine is an efficient and precise device used to cut a variety of glass materials. This article will give you an in-depth look at the inner workings of glass cutting machines, their different types, application areas, and maintenance tips. Let’s get expert insights!

1.Working principle

The glass cutting machine contacts the glass surface with the cutter and applies appropriate pressure, causing the glass to break and cut along the desired cutting line. Here are a few main working principles:

Cutting head: Glass cutting machines usually use diamond cutting heads. The diamond blade on the cutting head is very hard and capable of cutting glass when the right amount of pressure is applied.

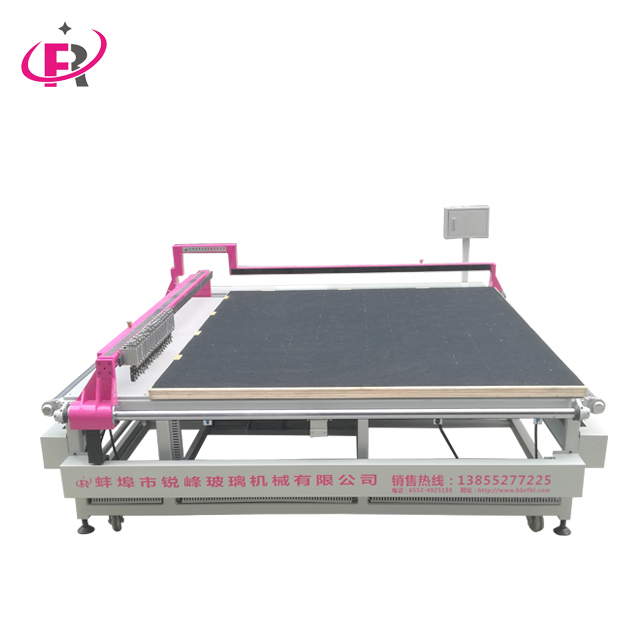

Pallet system: The glass is placed on the cutting machine's pallet. The tray system provides stable support and ensures the glass does not slip or move during the cutting process.

Pressure Control: Glass cutting machines often have adjustable pressure controls. Operators can adjust the appropriate pressure to ensure cutting results according to different types and thicknesses of glass materials.

2.Common types and application fields

Manual glass cutter: This type of cutter cuts glass by manually operating the cutting head. They are often used for simple glass cutting tasks such as home DIY projects or small glass processing workshops.

Semi-automatic glass cutting machine: Semi-automatic cutting machines are equipped with electric or pneumatic systems that control the glass cutting process through buttons or foot pedals. These cutting machines are more suitable for medium-sized production environments, such as custom glass factories or furniture manufacturers.

Fully automatic glass cutting machine: The fully automatic cutting machine is equipped with an advanced computer control system and sensors, which can automatically detect the size of the glass and perform precise cutting. They are suitable for use in large-scale production environments such as glass processing plants or the construction industry.

The application fields of glass cutting machines are very wide, including the following aspects:

Construction industry: used for cutting customized glass doors, windows, curtain walls and other building decoration materials.

Automotive industry: used for cutting and customizing parts such as front and rear windshields, windows and rearview mirrors.

Home industry: used to make glass furniture, mirrors and decorations, etc.

3.Maintenance skills

Proper maintenance can extend the life of your glass cutting machine and ensure that it continues to perform at its best. Here are some recommended maintenance tips:

Regular Cleaning: Keep your glass cutting machine clean, paying special attention to the cleaning of the cutting head and tray system. Use the proper tools and cleaners to avoid the accumulation of dust and broken glass.

Blade replacement: Check and replace the diamond blade on the cutting head regularly. A worn blade can result in poor cut quality or even damage to the glass material.

Adjust the pressure: Adjust the appropriate cutting pressure according to different types and thicknesses of glass. Avoid applying too much or too little pressure to avoid affecting the cutting effect.

Regular Inspections: Check various parts of the cutting machine regularly to make sure they are in good condition and tight. Repair or replace damaged parts promptly.

The glass cutting machine achieves efficient and precise cutting of glass materials through the cooperation of components such as the cutting head, tray system and pressure control. Different types of cutting machines play an important role in their respective fields of application. Proper care and maintenance can extend the life of your cutting machine and ensure it remains at peak performance.

I hope this article can help you better understand the working principle and maintenance skills of glass cutting machines. If you have additional questions, please feel free to ask!