Glass cutting machine is one of the necessary equipment in modern glass processing factory. Glass cutting machines can be divided into various types based on their function and mode of operation. This article will introduce in detail four common types of glass cutting machines, including glass cutting multi-function machines, glass cutting machines, fully automatic glass cutting machines and semi-automatic multi-function glass cutting machines. After reading this article, you still have more questions about glass cutting machines. If you have any questions, please contact the editor for more ordering information!

Glass cutting multi-function machine:

The glass cutting multi-function machine is a highly flexible and multi-functional glass cutting equipment. It has automatic loading, cutting and collecting functions, and is suitable for the mass production of glass plates of various shapes and sizes. This model usually adopts advanced CNC technology, which can realize automatic operation and diversified cutting modes through preset programs to improve production efficiency and precision. Glass cutting multi-function machines are widely used in construction, home decoration, automobile, and electronic industries.

Glass cutting machine:

Glass cutting machine is a common glass cutting equipment, mainly used to cut regular-shaped glass plates. This model positions and fixes the glass plate on the cutting table through the loading operation, and then cuts it according to the preset size and shape parameters. This glass cutting machine has the characteristics of easy operation, compact structure and high cutting accuracy. Widely used in construction, home decoration, glass crafts and other fields.

Fully automatic glass cutting machine:

The fully automatic glass cutting machine is a highly intelligent and automated glass cutting equipment. Through advanced control systems and sensing technology, automatic separation, conveying, cutting and collection functions can be realized. The fully automatic glass cutting machine not only improves production efficiency and processing quality, but also reduces the time and cost of manual operation and material handling. It is widely used in large glass processing factories such as building curtain walls, glass handicrafts, and furniture manufacturing.

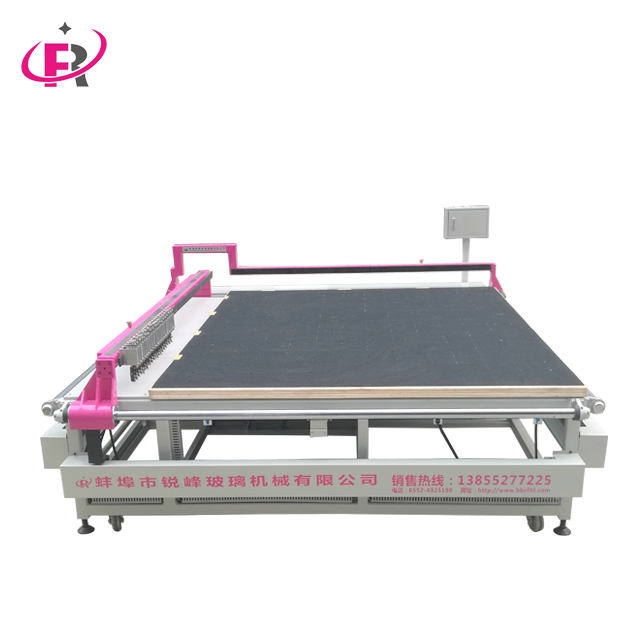

Semi-automatic multifunctional glass cutting machine:

Semi-automatic multifunctional glass cutting machine combines the features of manual operation and automated functions. It is usually equipped with a cutting table, positioning system and cutting tools, and the operator can manually position and cut as needed. This model is suitable for small and medium-sized glass processing factories or individual studios, and can meet daily cutting needs.

To sum up, different types of glass cutting machines have their own characteristics and application areas. Glass plate cutting multi-function machines and glass plate cutting machines are suitable for cutting regular-shaped glass plates; fully automatic glass cutting machines provide efficient, precise and continuous cutting solutions for mass production environments; while semi-automatic multi-function glass cutting machines are suitable for medium-sized Small glass processing place. Based on your actual needs and budget, choosing the right glass cutting machine can help improve production efficiency and processing quality, and promote enterprise development.