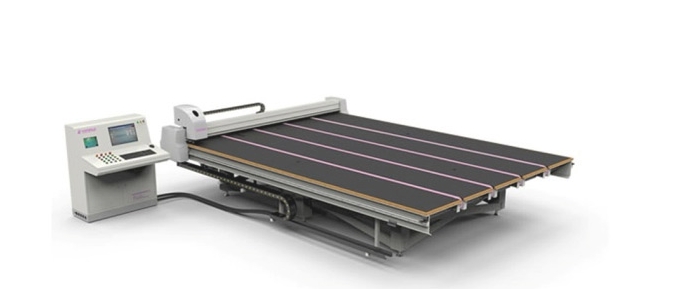

A fully automatic glass cutting machine is a machine that uses advanced technology and equipment to cut glass efficiently, accurately and safely. This article will introduce the working principle of a fully automatic glass cutting machine and its application in different fields.

working principle

The fully automatic glass cutting machine uses an advanced computer control system and a high-precision cutting head to achieve fast and accurate cutting of glass sheets. Its working principle mainly includes the following steps:

Data input: The operator inputs the size and shape data to be cut into the control system of the fully automatic glass cutting machine through the computer.

Glass positioning: The machine fixes the glass plate on the workbench through air pressure or vacuum suction cups to ensure that it does not move or shake during the cutting process.

Cutting path planning: Based on the input size and shape data, the control system of the fully automatic glass cutting machine will automatically plan the optimal cutting path to minimize waste and improve cutting efficiency.

Cutting operation: The cutting head cuts the glass plate through the high-speed rotating cutting blade according to the instructions of the control system. The high precision and stability of the cutting head ensures the smoothness and accuracy of the cutting surface.

Cleaning process: After the cutting is completed, the fully automatic glass cutting machine automatically removes the fragments and waste materials in the cutting area, and moves the glass plate to the next work step or takes it out.

Application areas

Fully automatic glass cutting machines are widely used in various fields, including construction, home decoration, automobiles, electronic products, etc. Here are a few common application cases:

Construction industry: The fully automatic glass cutting machine can cut large glass plates into the required size and shape according to the designer's requirements, and can be used for windows, curtain walls, partitions, etc. in buildings. Its efficient and precise cutting capabilities can greatly improve production efficiency and quality.

Home decoration: The fully automatic glass cutting machine can cut glass plates into various shapes of mirrors, dining table panels, vase bases, etc. according to personal needs. These customized products can meet consumers' needs for personalized home decoration.

Automotive industry: Fully automatic glass cutting machines are used for cutting front and rear windshields and windows of automobiles. Precise cutting capabilities ensure the fit of the glass to the car body, improving the safety and comfort of the car.

Electronic products: Fully automatic glass cutting machines are increasingly used in the manufacturing of electronic products, such as smartphones, tablets, LCD monitors, etc. It can cut glass sheets into touch screens and displays of various shapes and sizes to meet the needs of different products.

Advanced fully automatic glass cutting machine manufacturer

If you want to get an advanced fully automatic glass cutting machine manufacturer, ruifeng is your best choice. As a professional fully automatic glass cutting machine manufacturer, ruifeng can provide you with high-quality products and excellent services. Welcome to contact us for details Information!

Fully automatic glass cutting machines play an important role in various fields with their efficiency, accuracy and safety. With the continuous advancement of technology, fully automatic glass cutting machines will continue to develop, bringing more convenience and innovation to people's lives and work.