A glass cutter is a professional tool used for precise cutting and processing on glass. Weight is an important consideration when using a glass cutter. This article will explore the effect of weight on a glass cutting machine and share some tips for cutting glass efficiently.

Part One: Effect of Weight on Glass Cutting Machine

Stability: Heavier cutting machines are generally more stable, reducing vibration and shaking, and providing more precise cutting results. Lighter cutting machines may create instability during operation, causing cut deviations or damaging the glass.

Cutting Power: Heavier cutters generally have more cutting power and can handle thicker glass sheets more easily. In comparison, lightweight cutters may require more effort to complete the same cutting task.

Operability: A moderately weighted cutter is easier to operate and more comfortable for workers who use it for long periods of time. An overweight cutting machine can cause fatigue and inconvenience, affecting operating efficiency.

Part Two: Tips for Efficiently Cutting Glass

Use the right cutting blade: Choosing the right cutting blade is very important. The quality of the blade and the sharpness of the cutting edge directly affect the cutting effect. Make sure the blade is sharp and choose the appropriate blade type based on the thickness of the glass.

Control cutting speed: Cutting speed is one of the key factors affecting cutting quality. Cutting too fast may result in uneven cuts or cracked glass. Properly control the cutting speed to maintain a stable and uniform cutting process.

Use coolant: Using the right amount of coolant during the cutting process can reduce heat build-up and prevent the glass from warping or cracking. Coolant also lubricates cutting blades, improving cutting performance.

Accurate Measurements and Markings: Before cutting, make sure you take accurate measurements of the glass and use the appropriate tools to mark it. Accurate measurements and markings can help you maintain correct orientation and dimensions during cutting.

Pay attention to safety precautions: Cutting glass is a potentially dangerous job and requires safety precautions. Wear safety glasses and gloves to ensure the stability of the cutter and avoid placing your fingers too close to the cutting area.

Part Three: Efficient Glass Cutting Machine

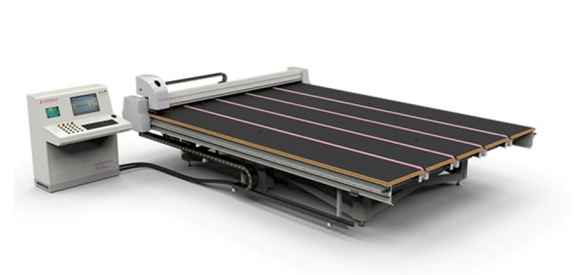

If you want to cut glass efficiently, it is crucial to get an efficient glass cutting machine. The following is the glass cutting machine compiled by the editor for everyone. It comes from the well-known glass cutting machine manufacturer in China: Ruifeng, as a professional As a manufacturer of glass cutting machines, Ruifeng can bring you high-quality products and excellent services! Welcome to contact us for more ordering information!

Weight is a key factor to consider when choosing a glass cutting machine. Heavier cutters are generally more stable and can cut harder, but excess weight can also lead to inconvenience and fatigue. Cutting efficiency and quality can be improved by adopting proper cutting techniques such as using suitable blades, controlling cutting speed, using coolant, etc. When cutting glass, make sure to pay attention to safety precautions to protect yourself and others.