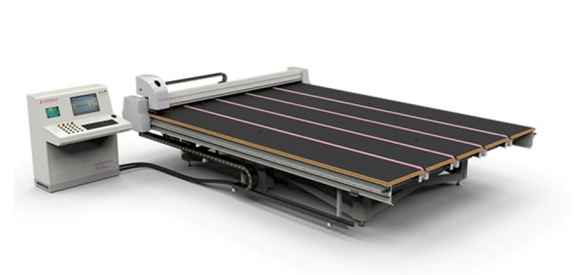

With the continuous development of modern architecture and home decoration, glass has become a widely used material. However, cutting is an essential step in the glass processing process. To improve efficiency and precision, glass cutting machines are widely used. Different cutting materials require different cutting machines. Let’s take a look at glass cutting machines for different cutting materials.

Ordinary glass

Ordinary glass is the most basic and common glass material. For ordinary glass, glass cutting machines need to be high-speed, efficient, and precise. Common cutting machines include manual cutting machines and automatic cutting machines. Manual cutting machines require operators to cut manually and are suitable for small batch production. Automatic cutting machines can automatically complete cutting tasks and are suitable for mass production.

tempered glass

Tempered glass is a kind of tempered glass with high strength, high impact resistance and high heat resistance. Tempered glass cutting machines need to have higher precision and stronger cutting power. Common cutting machines include water-cooled glass cutting machines, automatic tempered glass cutting machines and laser cutting machines. Water-cooled glass cutting machines use a water cooling system to ensure that excessive heat is not generated during the cutting process, thereby avoiding glass breakage. The fully automatic tempered glass cutting machine can automatically complete the cutting task and improve production efficiency. Laser cutting machines allow for greater precision and faster cutting speeds.

Multilayer laminated glass

Multi-layer laminated glass is a glass material made of a layer of PVB film sandwiched between two or more layers of glass. Laminated glass cutting machines need to have higher precision and stronger cutting power. Common cutting machines include multi-wheel cutting machines and laser cutting machines. The multi-wheel cutting machine can cut multiple layers of glass at the same time to improve production efficiency. Laser cutting machines allow for greater precision and faster cutting speeds.

Special glass

Special glass includes ceramic glass, crystal glass, film glass, etc. These materials typically require greater precision and greater cutting power. Common cutting machines include laser cutting machines, ultrasonic cutting machines and water jet cutting machines. Laser cutting machines allow for greater precision and faster cutting speeds. Ultrasonic cutting machine can achieve non-destructive cutting. Water jet cutting machines use high-pressure water flow to achieve efficient and precise cutting.

In short, different glass materials require different cutting machines. When choosing a glass cutting machine, you need to choose according to actual needs and material characteristics to achieve the best cutting effect and production efficiency.