Glass cutting is a critical process in many industries, from construction and automotive to interior design and consumer electronics. It requires precision, productivity, and safety to ensure high-quality outcomes and efficient operations. Traditional manual glass cutting methods have their limitations, particularly in terms of accuracy and speed. This is where semi-automatic glass cutting machines come in, providing a solution that addresses these challenges while offering additional benefits. Let's explore the key advantages of these machines and why they are becoming an increasingly popular choice for glass processing businesses.

Improved Precision

One of the most significant advantages of semi-automatic glass cutting machines is their ability to deliver precise cuts consistently. These machines use advanced technology, such as computer numerical control (CNC) systems, laser guidance, and digital templates, to achieve high accuracy in cutting glass. This level of precision is challenging to achieve with manual methods, where human error can lead to inconsistencies and rework.

Semi-automatic machines can follow complex patterns with ease, allowing for intricate designs and shapes. This capability is crucial in industries like automotive, where precise glass components are essential for vehicle safety and aesthetics. Similarly, architectural glass requires precision for structural integrity and seamless installation. By reducing the risk of errors, these machines improve the overall quality of the final product.

Increased Productivity

Productivity is another area where semi-automatic glass cutting machines excel. These machines streamline operations by automating many of the repetitive tasks involved in glass cutting. Unlike manual methods, which rely on individual operators' skill and speed, semi-automatic machines work at a consistent pace, significantly reducing the cutting time per piece.

The result is a substantial increase in throughput and faster turnaround times. This efficiency allows businesses to meet tight deadlines and accommodate larger orders without compromising quality. Additionally, semi-automatic machines can handle multiple cutting tasks simultaneously, further boosting productivity.

Enhanced Safety

Safety is paramount in any industrial setting, and semi-automatic glass cutting machines offer enhanced safety features compared to manual methods. These machines are designed to minimize direct contact between operators and cutting tools, reducing the risk of cuts, abrasions, and other injuries. Features like safety guards, emergency stop buttons, and automated shutdown mechanisms add additional layers of protection.

In contrast, manual glass cutting involves more hands-on interaction with sharp tools and fragile materials, increasing the risk of accidents. By incorporating semi-automatic machines into their processes, businesses can create a safer work environment, reducing workplace injuries and associated costs.

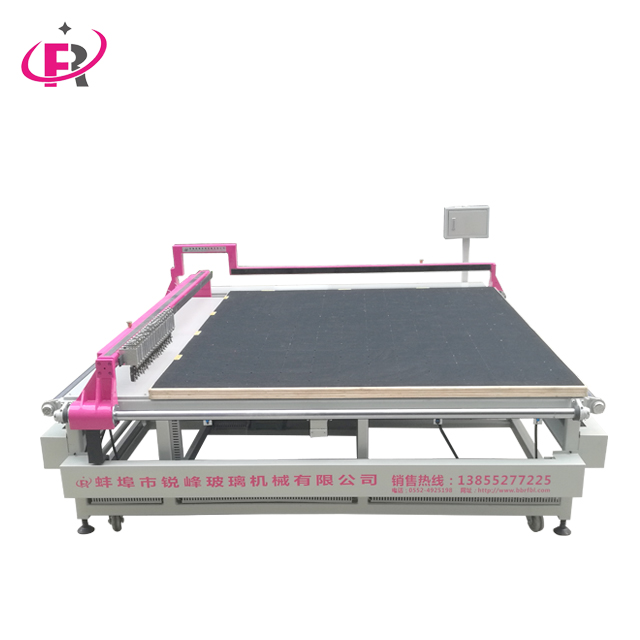

How to choose a semi-automatic glass cutting machine

If you are considering how to choose a semi-automatic glass cutting machine, you might as well try ruifeng. As a professional semi-automatic glass cutting machine manufacturer, ruifeng can provide you with high-quality products and services. Welcome to contact ruifeng for detailed ordering information and content!

Cost Efficiency

While the initial investment in semi-automatic glass cutting machines may be higher than manual equipment, the long-term cost savings justify the expenditure. These machines reduce material waste by making precise cuts, ensuring that glass sheets are used efficiently. The reduction in rework due to errors also contributes to cost savings.

Furthermore, the increased productivity translates into higher output and revenue generation. As businesses optimize their operations with semi-automatic machines, they can achieve a favorable return on investment (ROI) over time. Reduced labor costs, fewer workplace injuries, and less waste all contribute to improved cost efficiency.

Semi-automatic glass cutting machines offer a range of benefits that make them a valuable asset for any glass processing business. From improved precision and increased productivity to enhanced safety and cost efficiency, these machines address the limitations of manual methods while providing additional advantages. By embracing the capabilities of semi-automatic machines, businesses can optimize their production processes, deliver high-quality products, and create a safer working environment. If you're in the glass industry and looking to improve your operations, consider integrating semi-automatic glass cutting machines into your workflow. The results will speak for themselves.